Our team provides a robust and fully integrated process driven manufacturing facility with turnkey capabilities. Over 90% of our project executions are handled in-house. Our cross-trained skilled craftsmen execute best in class production techniques spanning sheet metal, CNC machining, welding, coating, as well as final assembly.

Logistics Spares

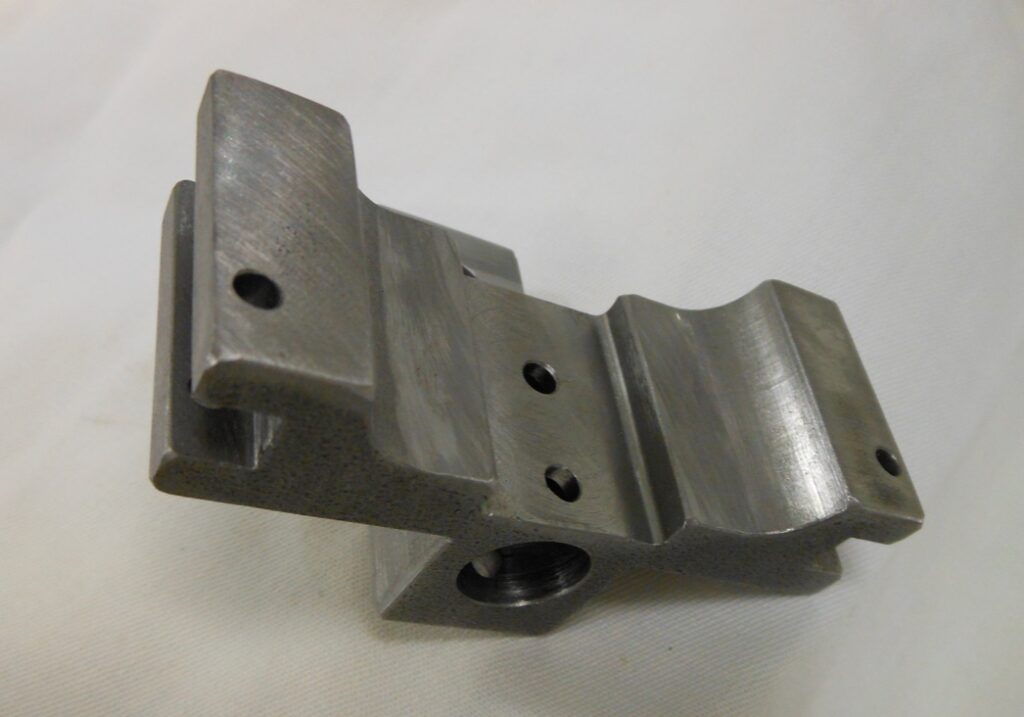

Machined Components

The machine shops (3) make up the majority of our facilities housing over 40 Computer Numerical Code (CNC) horizontal and vertical machining centers and CNC lathes. Three, Four, and Five Axis mills along with FMS (flexible manufacturing) utilizing “Mazak Palletech” palletized systems for 24/7 operations. Some of our machining centers have up to 12-foot travel, and we boast a cadre of quick turn lathes, plasma and 2D laser operations as well.

Hardware

We utilize aerospace components, commercially purchased off the shelf components and locally manufactured components to support our customers with parts, next higher sub-assemblies and assemblies.

Subassemblies & Assemblies

As part of our logistics spares mission, D&D can manufacture to any level of completion. Much of our business is providing spare parts, sub-assemblies and completed assemblies for both our commercial and Department of Defense customers.

Component/Assembly Testing

All subassemblies and assemblies are produced and tested in-house. We operationally test all manufactured components to supplier provided test procedures as required. Tests include continuity, isolation, hydraulic, servo-hydraulic actuator testing, operational and power on. Our expertise also includes, load testing, cold climate, stress and mobility testing.