We provide manufacturing solutions, specializing in design, machining, fabrication, assembly, and repair of aerospace ground support equipment for commercial and Department of Defense applications. Our team brings over 40 years of experience delivering diverse and comprehensive manufacturing solutions to support the needs of our warfighters. Manufacturing a wide variety of support equipment in the arenas of aerospace, munitions, mobile, naval, and tactical vehicular applications.

Aerospace Ground

- PT90-F Engine Lift Trailer

- TT90-F-507 Engine Transport Trailer

- Ground Handling Tire and Wheel Dolly

- C-17 Engine Cradle

- APU Install/Removal Dolly

- Secondary Barrier Trailer

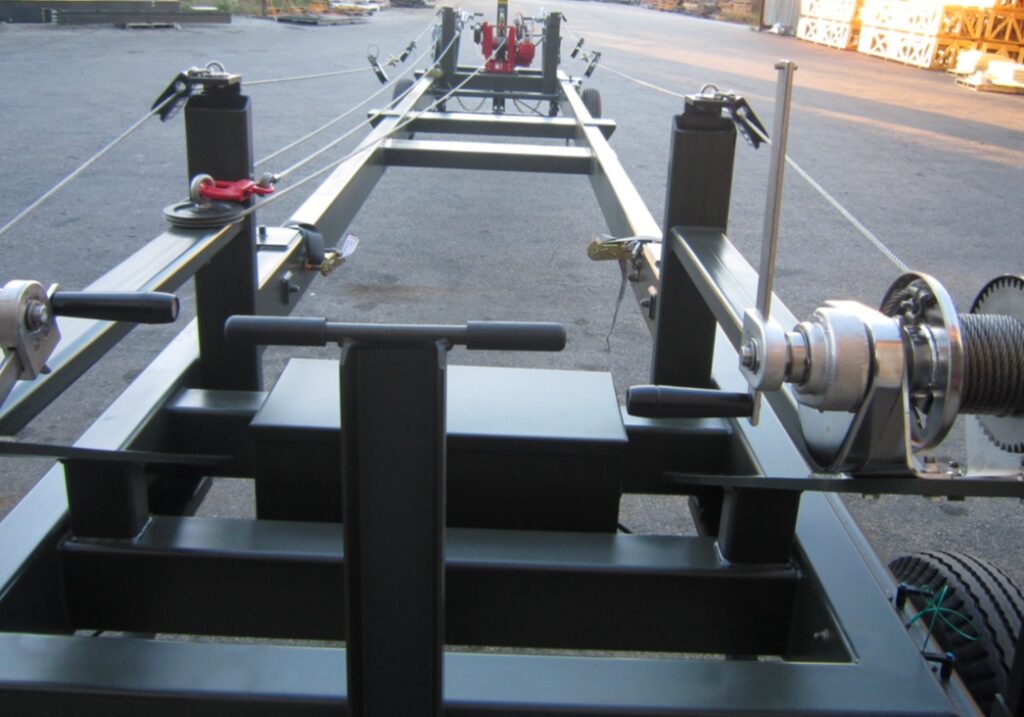

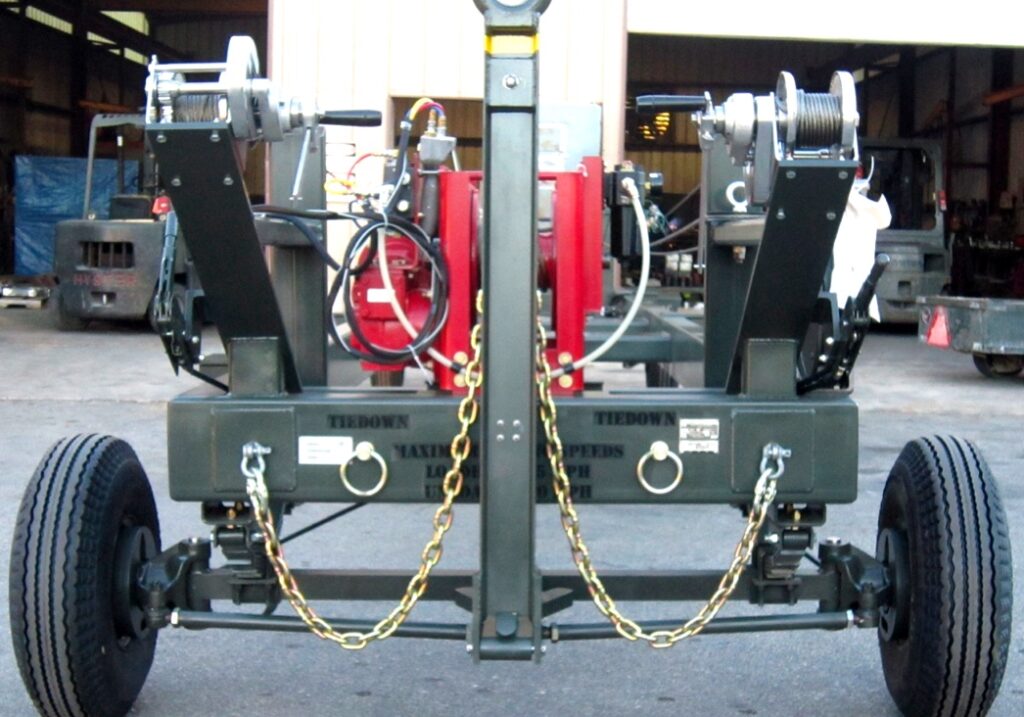

PT90-F Series, Engine Positioning Trailer

The photos above depict the PT90-F engine positioning trailer providing for the maintenance, removal and replacement of the four Pratt and Whitney engines on the C-17 Globemaster III aircraft. It incorporates work platforms, ladders, auxiliary platforms, winches and controls required to remove and replace the aircraft engines. It also contains electro-hydraulic systems to allow the trailer to move through 5-axis of travel to facilitate engine mating. It contains I-beam rails which mate with various support equipment to facilitate the removal, installation and roll transfer of a cradle mounted engine.

D&D has manufactured these units under US Air Force contracts as well as the Boeing C-17 Support Program and Foreign Military Sales.

- PT90-F-507 NSN: 1730-01-508-6426

- PT90-F-509 NSN: 1730-01-560-2167

- PT90-F-511 NSN: 1730-01-595-6401

TT90-F-507 Engine Transport Trailer

The engine transport trailer provides a mobile capability to transport engines to and from storage and the aircraft. The trailer uses the same I-beam system to work in tandem with the PT90-F lift trailer to facilitate loading and unloading from one trailer to another.

- NSN: 1740-01-525-1884

Ground Handling Tire and Wheel Dolly

The Transport Tire Trailer provides a quick response capability for tire change outs on the C-17 Globemaster aircraft. D&D designed, developed and tested the trailer at the US Army Aberdeen Proving Ground putting it through reliability testing over a variety of terrain under differing weather conditions. The Trailer is designed with a hand operated four wheel lifting hoist to raise the landing gear to remove the tires. It will hold 8 inflated or deflated aircraft tires.

C-17 Engine Cradle

The engine cradle is designed to secure a Pratt and Whitney PW2040 turbofan engine (military designation F117-PW-100) to various ground support trailers for installation, removal and transport.

It is designed to fit on I-beam rails used on engine transport and engine positioning trailers.

Pictured left is an engine cradle being pushed into place on a PT90 Engine Positioning Trailer prior to an engine change-out on a C-17 Globemaster III aircraft. The US Air Force photo was taken by SSgt Sheila deVera. The airmen shown are from the 8th Expeditionary Mobility Squadron.

- NSN: 1730-01-250-9737

- P/N: 17G230005-1

APU Install/Removal Dolly

This unit is hydraulically/mechanically operated dolly for the removal and installation of the auxiliary power unit on the C-17 Globemaster III aircraft. It’s multi-axis platform allows for aligning with the APU on the aircraft.

Secondary Barrier Trailer

This trailer functions as support for the maintenance, removal, replacement, and provides mobile capability to transport, the C-17 long range fuel tank barrier. The US Air Force photo on the left shows the barrier trailer in use inside a C-17 Globemaster III cargo aircraft.